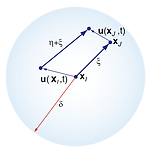

In continuum mechanics, the internal force is determined by the local deformation gradient and corresponding constitutive material model, while, in Peridynamics, it is replaced by an integral form with a set of non-local bond forces within a horizon. [Silling 2000] This makes Peridynamics very suitable in material failure analysis. The bond-based Peridynamics was implemented in LS-DYNA [1,2] using a framework of the discontinuous Galerkin FEM. FEM models can be used as input for Peridynamics analysis.

-

Advantage

-

Model crack initiation and propagation by breaking bonds

-

Capable to model complex failure modes

-

Mixed modes in 3D solid

-

In-plain failure, crossing lamina and delamination in laminate

-

-

-

Current implementation [kw][ex]

-

Bond-based Peridynamics

-

Discontinuous Galerkin FEM [1]

-

FEM model with detaching nodes as input

-

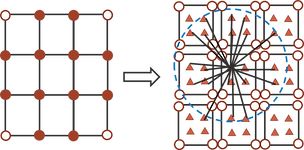

Bonds defined between integration (stress) points

-

-

Automatic conversion of material property [2]

-

From elastic modulus to bond micro modulus

-

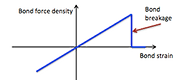

From fracture energy release rate to bond critical stretching

-

-

3D solid & elastic material with brittle failure [kw]

-

Explicit analysis

-

-

Limitation

-

Elastic material with fixed Poisson's ratio (0.25)

-

-

Keyword

-

Application

-

Brittle material failure, e.g. windshield impact

-

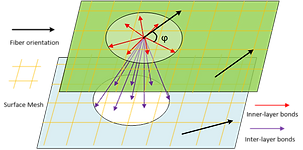

Laminate failure, e.g. compression, drilling, jointing & impact

-

Discontinuous Galerkin: FEM model with detaching nodes

Inner-/inter-layer bonds with uniform mesh for laminate

Non-local horizon & bond force